3D printing company Milkshake3D has created a new SLA printer capable of smooth detailed prints. The machine combines high quality reproduction of designs with rapid production.

As a result, the resin-based 3D printer has significant applications in the model making and jewelry markets. With use of a unique web platform, the device can also be controlled remotely.

Milkshake3D are launching a crowdfunding campaign on Kickstarter to bring the digital-light-processing (DLP) 3D printer to a select group at a lower price. Furthermore, the new desktop device provides users with a more affordable 3D printing option.

What’s new with Milkshake3D

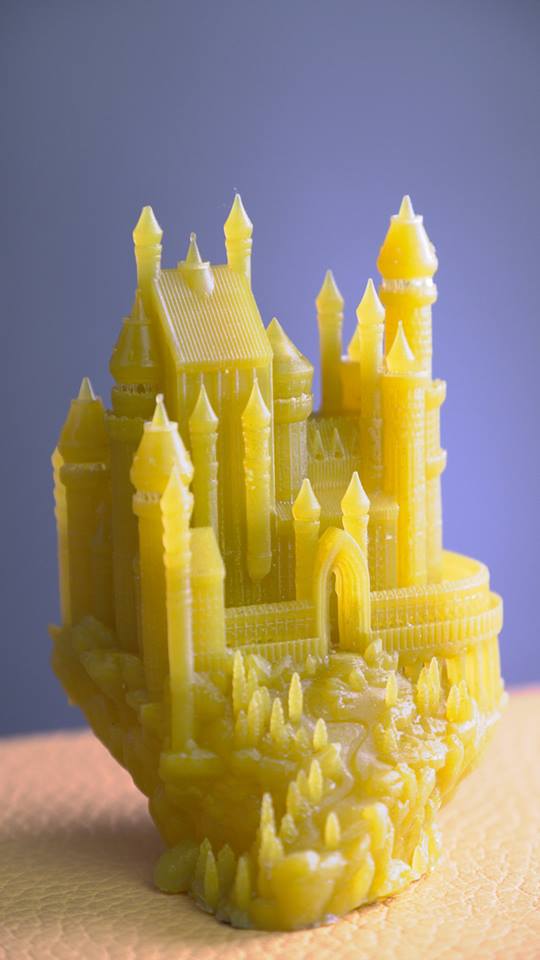

SLA printers are known for their incredible detail and Milkshake3D offer resolution down to 20 micrometres. Feature sizes of as low as 50 micrometres are also possible.

However, while Stereolithography printers are famed for their detailed finishes, 3D prints can be prone to cracking. The SLA process typically involves lifting prints from a vat of resin and this can lead to cracking and or detaching from the build plate. This problem is exacerbated when printing larger objects, such as the designs that the Milkshake3D demonstrates.

Milkshake3D take a top-down approach by which the company say this means the 3D prints will be immune from such issues.

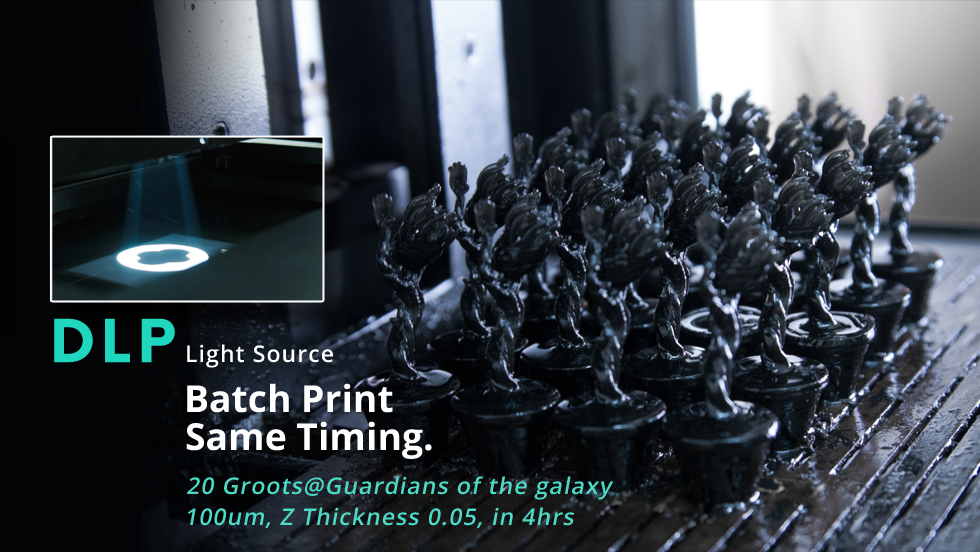

Batch printing

With a large build platform, Milkshake3D’s printer is also well-suited for batch printing. It allows multiple objects to be printed simultaneously and in the same amount of time as one, given that SLA print time is not constrained by width or depth but rather height.

The 3D printer can print larger models up to 288 x 162 x 160mm in size.

Wiper System

To optimize the build platform after each print, the Milkshake3D uses a wiper system. This system maintains a smooth consistent surface for prints and refills resin for the next job.

Software

The company, operating from Hong Kong, has created a specialized software application for the printer. According to their website, the Milkshake3D software slices large models 3x faster than competitors. Referencing a model size of over 400MB, the model takes only an hour to slice rather than nearly five in comparison to others.

Jewelry

The Milkshake3D is well suited for creating jewelry casts. Using a purposely formulated resin, the machine can print casts to be burned out and to make unique detailed jewelry. This material and 3D printer enables the creation of complex jewelry casts in a significantly faster manner than traditional process.

More details about the Milkshake3D printer are available here.

Specifications

Printing

Technology – Stereolithography (SLA)

Features – Native 1080p DLP projector, Wiper System

Build Volume – 288 x 162 x 160 mm

X/Y Resolution – 50um, 100um, 150um (Auto adjust)

Layer Thickness – 20 – 100um

Hardware

Dimension – 420 x 380 x 840 mm

Weight – 35kg

Power Requirements – AC100 – 240V 50/60Hz

Connectivity – Wifi, Ethernet

Operation System – Web control on all OS and mobile devices: Windows, MacOS, Android, iOS, Linux.

Featured image shows Milkshake3D prints. All images and photos via Milkshake3D.