Global trade group Additive Manufacturer Green Trade Association (AMGTA) has announced a systematic review into the environmental sustainability of metal 3D printing.

The organization’s first literary-based appraisal will be carried out by Jeremy Faludi, Ph.D, a researcher of sustainable engineering, with the aim of promoting the green benefits of additive manufacturing (AM).

“This project will provide our membership and the public in general with an excellent survey of existing research on the sustainability benefits of AM. Dr. Faludi is a renowned researcher within this field, and we are looking forward to understanding better the existing scope of research on this topic,” said Sherry Handel, the AMGTA’s Executive Director.

AMGTA’s green trade mission

Co-launched by Florida-based metal 3D printing service Sintavia at Formnext in 2019, the association’s objective is to promote the green benefits of 3D printing. AMGTA is a non-commercial, unaffiliated organization, that is open to any additive manufacturer or industry stakeholder that meets its sustainability criteria. In order to join the group, applicants must have generated most of their revenue from AM, adopted waste reduction measures and actively promoted the non-commercial green benefits of 3D printing.

Sherry Handel was appointed as the group’s first Executive Director in late February 2020, with the remit of educating the public about the environmental benefits of AM, promoting its adoption, and growing the organization’s membership. Ms Handel was due to make her first public appearance in her new role, by serving as a moderator on a leadership panel at RAPID + TCT 2020, but the event was postponed due to the Covid-19 pandemic.

According to Brian Neff, Chairman of the AMGTA Board of Directors, the group was founded to draw attention away from the cost and time benefits of 3D printing, and highlight its often-overlooked environmental benefits.

“We founded the AMGTA because too often in additive manufacturing we focus on the cost and time benefits of the technology, and do not equally consider the very real environmental benefits of AM over traditional manufacturing. These benefits include improved end-use design utility and improved industrial ecology of the fabrication process itself. The AMGTA’s purpose is to raise awareness of these benefits within end market segments, in order to accelerate the adoption rate of the technology,” said Neff.

The new AMGTA research project

Dr Faludi, who will lead the research, is an assistant professor of design engineering at the Technical University of Delft in the Netherlands. He specializes in designing for the circular economy and green 3D printing and holds a Ph.D. in Mechanical Engineering at the University of California Berkeley, a Master of Engineering in Product Design at Stanford University, and a B.A. in Physics from Reed College.

The AMGTA-commissioned research paper will comprise a literature review of existing studies that describe the environmental benefits of AM compared to traditional manufacturing methods. Where appropriate, the independent study will also examine areas where 3D printing has an adverse effect on the environment, compared to traditional production techniques.

“This research may also reveal areas in the manufacturing process where AM could cause higher environmental impacts than older manufacturing methods. Through rigorous, independent, and ongoing research, the AMGTA will publish research findings, and share with industry and other key stakeholders what our eco-footprint is now, and what we will need to focus on in the future to be more sustainable,” said Handel.

Additive manufacturing’s green new deal

Academic institutions have also sought to assess the environmental impact of 3D printing and come to varying conclusions.

A peer-reviewed scientific journal was published by the Center for Industrial Ecology (CIE) at the Yale School of Forestry & Environmental Studies (F&ES) in December 2017. Aiming to examine the environmental, energy, and health impacts of AM, the paper surmised that it was “too early to label 3D printing as the path to sustainable manufacturing.”

French researchers from Grenoble Alpes University evaluated the environmental impact of 3D printing, with a case study focused on the production of orthotic insoles, in May 2017. The research team found AM to be more environmentally friendly than conventional manufacturing methods, due to the considerable time saved during production.

Researchers from MIT, Yale, and the University of Nottingham presented further analysis on the environmental performance of 3D printing in September 2018. While acknowledging the accessibility benefits of AM, and its use of recycled materials, the research team concluded that the technology is not zero-waste, and more can be done to enhance its sustainability.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

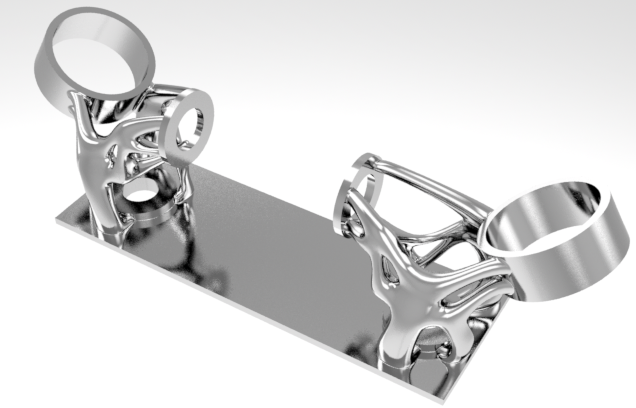

Featured image shows the AMGTA logo. Image via the AMGTA.