Formnext is over already. The build-up starts earlier every year, and with four show floors, it can be a challenge to see everything.

Fortunately, the 3D Printing Industry team was out en masse to leave no booth unobserved, no Calendly unbooked, no comms team uncommunicated, no press release unpursued.

After a long week of traipsing around Frankfurt, a degree of uncertainty can set in. “Launch” can have multiple meanings. Is the printer commercially available, shown for the first time, or still a twinkling render in the eye of a visionary CTO?

On and off the show floor, Formnext provided a banquet of off-the-record conversations. Did that CEO really say that? Did the jovial background hum of Champions bar/ Rave Til AM / Thursday night closing party sonic assault provide a forum for robust discussions? Thematically, I will say that intensifying “macro-economic and geopolitical conditions” have toughened resolve to beat out the competition.

Here’s the complete* round-up of the 3D printing news from Formnext 2023.

*Yes, this is probably not the complete round-up of all the news; we have plenty more to add from our interviews, and if you have more news, please send it our way! In the meantime, bookmark this page for updates and ease of reference.

Voting closes soon in the 2023 3D Printing Industry Awards.

Expanding the 3D printing material palette

ArcelorMittal entering the metal additive manufacturing powder market is likely to be among the biggest news in the materials space for the industry. I caught up with the CEO of the new business unit to hear the company’s plans and how the steel giant sees prospects.

Thermosets and thermoplastics, the latter is most likely to be found in the 3D printing industry. This year, many companies brought thermoset materials and processes to Frankfurt.

Chromatic 3D Materials were hard to miss; the Minnesota-based company brought out the Anouk Wipprecht-designed dress 3D printed using ChromaFlow 70, a heat-resistant material capable of stretching more than four times its length without breaking. Chromatic also showed a new rigid material during Formnext 2023, ChromaMotive D65, a Shore D thermoset polyurethane.

France’s Lynxter demonstrated silicone 3D printing. Lynxter has introduced the S300X, an industrial silicone 3D printer offering unprecedented robustness and integrated support printing technology, which enhances design potential in medical and industrial silicones and polyurethanes. The Lynxter S300X is equipped with two tool heads configured in Independent Dual Extrusion (IDEX), allowing for the creation of main parts and water-soluble support structures without cross-contamination. This printer serves various industry needs, including producing surface treatment masks, custom seals, soft robotics, and medical applications like orthoses and prostheses.

One application using silicone 3D printing on display was found in the startup zone, with challenge winner Odapt. Ivana Llobet, CEO and co-founder of Odapt told me how her company uses 3D printing to perfectly match an individual’s anatomy and provide a solution to users of ostomy bags.

Also working with silicones, and also from France is 3Deus Dynamics. The company describes its powder bed and extrusion hybrid system as “Dynamic Moulding.” Since launch in 2020 the company has developed its technology to a level where showcasing is now possible, we took a closer look at 3Deus Dyamnics and Dynamic Moulding here.

RLP demonstrated another approach to elastomer extrustion using a gel material which takes the place of traditional supports to allow non-planar 3D printing. The technology debuted in 2017, and more recently, we profiled Rapid Liquid Print’s approach to working with foams, rubbers, and silicones. The 3D printing process runs at room temperature and requires no post-processing. The silicone-based applications include custom medical solutions for amputees. At present, the commercialization route is via selling the service rather than 3D printers.

Other lesser-spotted materials for 3D printing included ceramics and glass.

Poland’s Sygnis displayed several enticing items, including part of the 3W: water-hydrogen-carbon project and glass 3D printing. This deep tech company is also behind the Zmorph Fab multitool 3D printer.

Also working on the 3D printed glass was Maple Glass Printing. The Maple 3 is an extrusion-based 3D printer that can use recycled glass to 3D print. The Australian company has previously worked with the international architects Foster & Partners firm.

XJET was unable to attend Formnext this year as a company due to events in Israel, although at least one exec was in attendance. Recent partners such as Ceramaret and CeramTec would have likely been able to provide more insights into applications of the Carmel 1400C Additive Manufacturing system.

Evolve Additive Solutions added Nylon PA-11(A) and Gray ABS to its material portfolio and announced STEP Parts Now, a production service focused on serial production with 3D printing.

New 3D printer launches and showcases at Formnext 2023

Metal 3D printing systems – Category: Laser Powder Bed Fusion

The Renishaw RenAM 500 Ultra L-PBF metal additive system had people queuing for a look. Stephen Crownshaw, AM Business Manager EMEA, took rightful delight in telling me about the innovations present in the latest system from UK-based Renishaw. These included the eye-catching TEMPUS method that saves time on every layer.

3D Systems launched the DMP Flex 350 Triple, the latest in the series of metal 3D printers. The DMP Flex 350 Triple, is a compact, three-laser 3D printing system. This new configuration stands out for its versatile Removable Print Module (RPM) concept, which supports two different RPM modules with varying build volumes. The DMP Flex 350 Triple is unique in its class, offering a new RPM with a large build capacity of 350mm x 350mm x 350mm, alongside the standard RPM that has a build volume of 275mm x 275mm x 420mm. This makes it the most compact system capable of supporting a 350mm x 350mm x 350mm build area, ideal for cost-effective production of diverse parts such as impellers and cooling plates. The interchangeable RPMs add to the system’s application flexibility.

The DMP Flex 350 Triple also features an advanced 3-laser load-balanced printing capability, ensuring optimal multi-laser balancing and seamless surface quality without roughness or seams where multiple lasers converge. It can process a wide array of materials, suitable for various applications. This includes different aluminum alloys for thermal management and lightweight structures, nickel-based alloys for high-temperature corrosion-resistant applications, and 316L stainless steel, commonly used in industries like petrochemical, food, and pharmaceutical. The DMP Flex 350 Triple is currently available for order, with the new RPM for larger builds expected to be generally available in July 2024.

Australia’s Aurora Labs announced the AL250, transitioning from the Aurora Labs RMP-1 metal 3D printer model to the newly developed laser powder bed fusion machine. The AL250, boasting advanced technical features, will serve a dual purpose: it will enhance the company’s printing bureau services with its superior capabilities and act as a demonstrative model for future sales to customers. A key feature of the AL250 is its bidirectional recoating capability, powered by MCP technology. This innovation reduces recoating time and cuts production costs by allowing for extended laser exposure times. Such efficiency is crucial for rapidly prototyping and executing serial production runs of custom parts or components at cost-effective rates, especially for items not feasible with traditional manufacturing methods.

Ermaksan from Turkey presented the ENAVISION 120. In 2019, we reported on a larger metal 3D printer from the company at Formnext. The latest system targets a growing niche for users who demand smaller systems.

AMCM, an affiliate of EOS based in Germany, has announced its latest metal Laser Beam Powder Bed Fusion (PBF-LB) 3D printer, the AMCM M 8K. An advancement from its AMCM M 4K system, the new printer features eight 1kW lasers and an impressive build volume of 800 x 800 x 1200 mm. The development of the M 8K is supported by a national grant, primarily to assist aerospace company ArianeGroup with its Ariane 6 program under the European Space Agency (ESA). The printer’s initial application will be in producing large combustion chambers for ArianeGroup’s Prometheus rocket engine, with each component being over 1,000 mm tall and 800 mm in diameter, made from CuCr1Zr. Martin Bullemer, the Managing Director at AMCM, anticipates the M 8K System to be operational within a year, with the first 3D printed combustion chambers expected to be delivered to ArianeGroup by the end of 2024.

EOS showcased the upgraded EOS M 300-4, a system initially launched in 2018 at IMTS. Commercially available in February 2024, the enhanced system features a boost from four 400W lasers to 1KW lasers.

Also upgraded for Formnext 2023 with the Trumpf TruPrint 2000, a system announced in 2019. Here, laser power increases from 300 watts to 500-watt lasers, and a new square build plate replaces the circular option, providing a 30% build size boost.

SLM Solutions, now operating under Nikon SLM Solutions, has revealed its new brand identity in a “golden hue.” The company is showcasing the capabilities of the NXG XII 600 machine, equipped with 12 lasers of 1 KW each and a build envelope of 600x600x600 mm. Touted as the fastest machine on the market, it is 20 times faster than a single laser machine. It has a function for various spot sizes, driving productivity and reliability. Aimed at serial production for high-volume applications, it has automated features like automatic build cylinder exchange and external preheating and depowdering stations. It represents a significant leap toward integrating additive manufacturing into mainstream production lines.

Kurtz Ersa‘s Flying Ray is pioneering the production of large parts and series components in metallic 3D printing. The Flying Ray is a multi-axis system utilizing vertically impinging laser beams, a design that stands out for its adaptive laser power and modular expansion capabilities. Its build processor and slicer promise optimal results, simplifying data preparation, and features an intuitive human-machine interface. The machine’s modularity allows for customization based on the number of lasers, length and number of axes, and the overlapping area of the swivel arms. The Flying Ray’s build chamber boasts a large space of 1,500 x 1,000 x 500 mm.

Directed Energy Deposition

Hwacheon has a history of over 70 years in the machine tool industry and has recently made its foray into metal additive manufacturing with the DMX 07 DED machine. Featuring 3D slicing with the DEXTru slicer, this Korean company’s debut machine targets the aerospace, oil and gas, and defense industries. They are actively seeking dealers in Europe to expand their reach.

Ponticon, based in Wiesbaden, Germany, had its high-speed DED on display. This system uses Extreme High-Speed Laser Metal Deposition (EHLA) technology, combining various alloying elements and controlling solidification rates to influence microstructural features. Ponticon’s pontiMAT system can rapidly produce and test hundreds of alloy samples per day, significantly enhancing the efficiency of material development.

Electron Beam Metal Additive Systems

Electron Beam metal additive systems were out in force.

UK manufacturer Wayland Additive retained a large booth dominated by the company’s NeuBeam-powered system. I caught up with the CRO earlier this year to hear why the Wayland Additive Calibur3 is set to make waves.

The JAM-5200EBM metal 3D printer, developed by Japanese company JEOL, has successfully passed the rigorous AMS7032 operational qualification (OQ) standards. This milestone also includes meeting the AMS7011 material standards for the Ti-6Al-4V alloy, thanks to applying post-deposition hot isostatic pressing (HIP). JEOL’s JAM-5200EBM is notably the first Electron Beam Powder Bed Fusion (EB-PBF) device to comply with AMS7011 requirements since its initial application on a different EB-PBF manufacturer’s model. The AMS7032 OQ standard measures an additive manufacturing powder bed fusion machine’s capability to consistently produce materials that meet specific requirements while maintaining process control and stability across numerous builds.

Freemelt, listed on Nasdaq First North, launching a new Electron Beam metal AM system, eMELT-iD, specifically designed to develop industrial applications. This new addition facilitates efficient product and application development and prepares for mass production. The eMELT-iD industrial machine marks a significant step in Freemelt’s strategy to establish itself as a productivity partner and a key contributor to enhancing customer value and service. Daniel Gidlund, CEO of Freemelt, highlights the model’s unique advantage: eMELT-iD’s seamless integration with eMELT-iM, which allows for an effortless transition from product development to serial production. This approach contrasts the industry’s standard practice of scaling up machines for productivity, as eMELT-iD is built upon the core technology for serial production derived from eMELT-iM.

Wire Arc Additive Manufacturing

Fronius showcased the potential of Wire Arc Additive Manufacturing (WAAM) for metal 3D printing. This technology emphasizes a high degree of flexibility in component geometry, especially for prototypes and small-batch production, with a high deposition rate of up to four kilograms per hour for steel materials. WAAM is particularly cost-effective compared to other additive processes, as it requires only a suitable welding system without the need for costly special equipment.

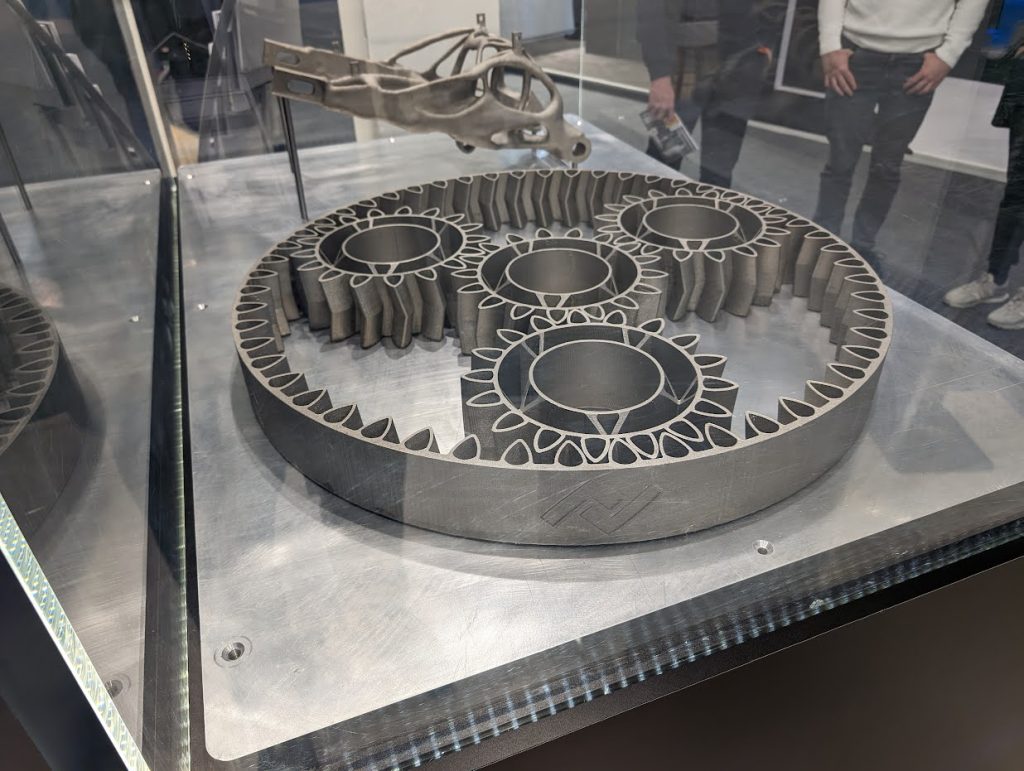

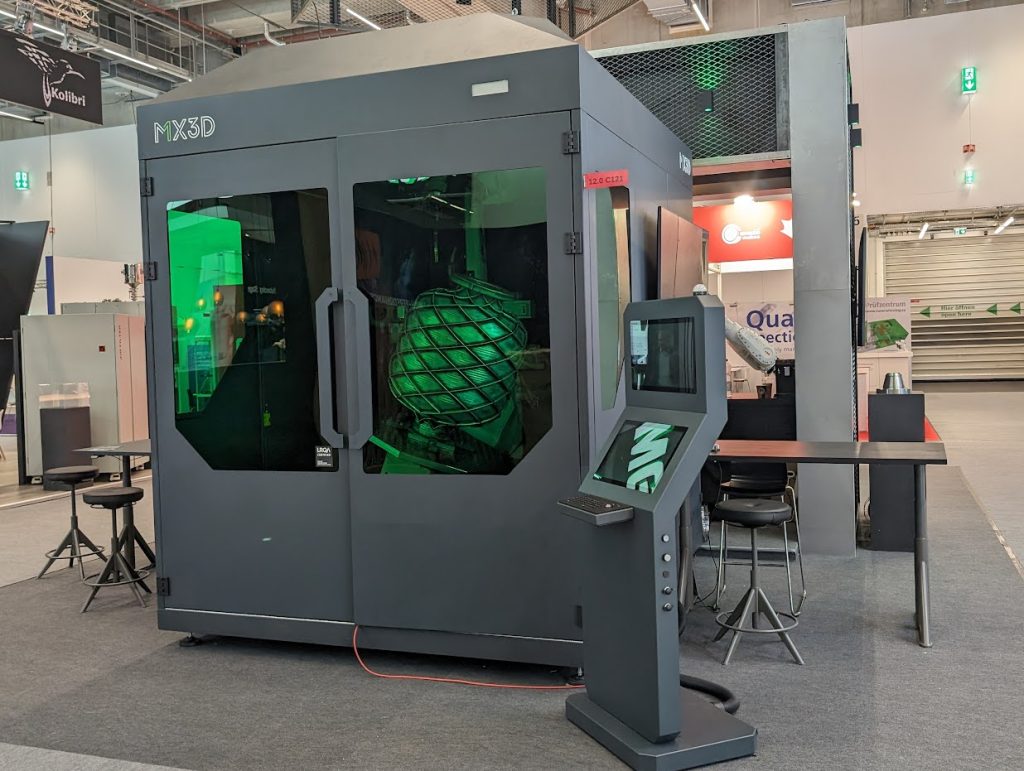

MX3D is known for its Robotic Wire Arc Additive Manufacturing (WAAM) technology, enabling 3D printing of large metal objects. The M-Systems, equipped with WAAM technology, offer a turnkey solution for printing medium-to-large-scale metal parts. MX3D’s MetalXL software enhances productivity through features like automatic calibration and advanced process control. With significant experience and a broad production capacity, MX3D serves a wide range of industries with its WAAM technology, suitable for both ferrous and non-ferrous alloy fabrication.

Vat Photopolymerisation for Metal 3D Printing

Holo brought the H200 PureForm lithographic metal 3D printing solution to display at Formnext. 3D Printing Industry interviewed the co-founder about Holo’s 3D printing technology.

Incus GmbH of Germany demonstrated the Hammer Pro40, a Lithography-based Metal Manufacturing (LMM) 3D printer. According to Incus, this new 3D printer has been designed to combine “unmatched cost efficiency” with high-quality 3D printing. Indeed, with a 3D print speed of up to 240 layers/h and up to 700 cm3/h, the Hammer Pro40 is seven times faster than the Lab35. The Hammer Pro40 also reportedly has a cost per cm3 that is four times lower than its predecessor.

Hybrid Systems

Additec, a metal 3D printer manufacturer from the United States, unveiled its latest metal 3D printer model, the Additec Hybrid 3, at Formnext 2023. This innovative printer integrates three distinct technologies: liquid metal jetting (LMJ), laser-directed energy deposition (LDED), and CNC (Computer Numerical Control) capabilities, all within a single platform.

Tritone‘s Dominant system leverages MoldJet technology for digital mold fabrication, allowing for additive manufacturing of metals and ceramics. With a build volume of 400 x 240 x 120 mm over six trays and a throughput of up to 1,600 cc/h, the Dominant can achieve densities up to 99% and offers a versatile layer thickness between 50-100µm. Tritone’s approach underscores the move towards high-precision, customizable manufacturing solutions within the 3D printing industry.

And what about users?

Rayvatek, a Taiwanese company, is now focusing on in-country production to support forces, a move influenced by geopolitics. The company’s mother company, Ti Space, is working on a Low Earth Orbit (LEO) satellite launch vehicle with a 3D printed rocket injector. As a service company, Rayvatek has over fifty 3D metal printers.

To be continued….

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows BWT Alpine F1 car at Formnext 2023. Photo by Michael Petch.