3D printing hardware manufacturer Mosaic Manufacturing has announced a whole host of new 3D printing products.

The Array product ecosystem includes four new multi-material FFF 3D printing systems, two new filament handling devices, and several thermoplastic filaments. Built to address the needs of high-volume manufacturing facilities, the mass product launch places a focus on high throughput 3D printing and scalability on the shop floor.

Chris Labelle, COO of Mosaic Manufacturing, explains, “Array’s impact on manufacturing comes from the benefits of enabling 3D printing for scaled applications. Flexible output, mass customization, faster turnaround times and unrestricted part geometries are now able to be accessed in production volumes of hundreds of thousands of parts per year.”

The Array 3D printing system

The flagship product in the Array ecosystem is undoubtedly the Array 3D printing system. The device contains four individual Element HT 3D printers (more on these below) working in tandem for round-the-clock part production. Each individual module is equipped with a Palette X material handling system, which can switch between filaments mid-print. As such, each of the four Element HT 3D printers is capable of printing with up to eight different filaments in a single part, including engineering materials such as PEEK and Ultem.

The Array machine also features an automatic part removal system that serves to substitute out print beds after every build is complete, replacing them with a fresh build platform in an automated manner. This ensures all four individual 3D printers are almost always active with less than 10% downtime, even when the operator has gone home for the night.

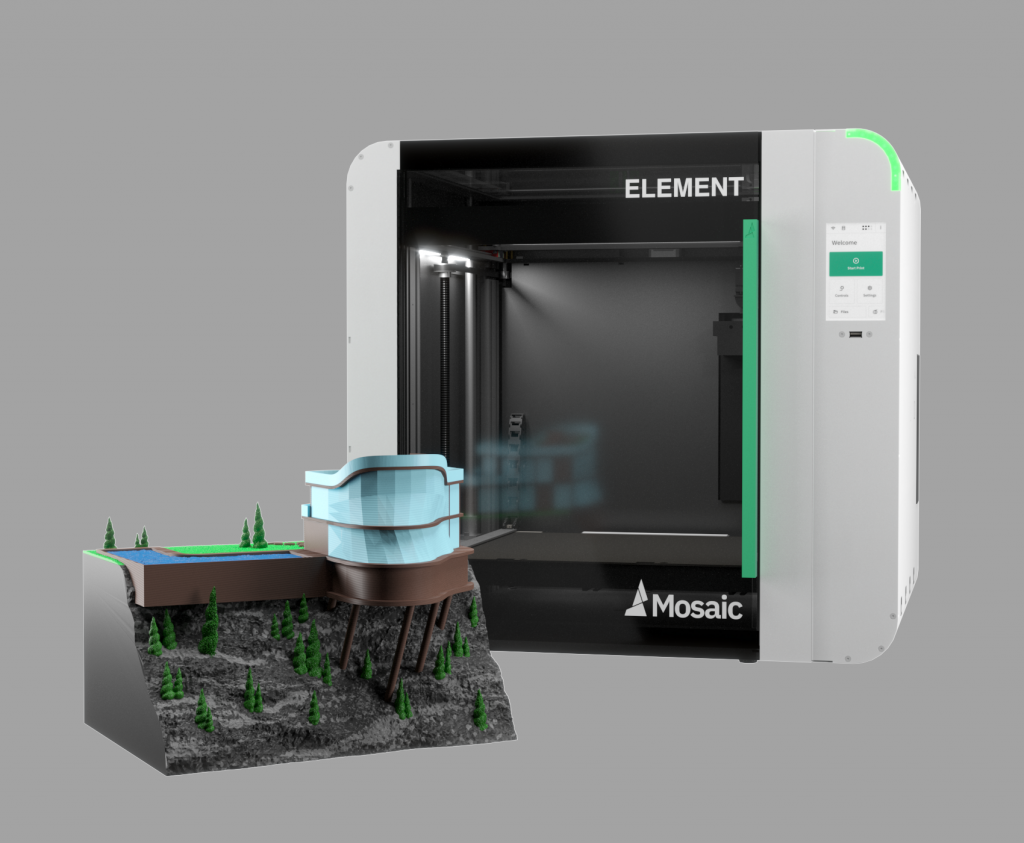

The Element HT 3D printer

Of course, not everyone will require an entire Array system. This is why Mosaic is also launching the Element HT 3D printer as a standalone device. The machine features a build volume measuring 355 x 355 x 355mm and comes complete with both a heated build platform (120°C) and a heated build chamber (80°C).

With a maximum nozzle temperature of 500°C, the Element HT is compatible with Mosaic’s entire portfolio of newly revealed 3D printing filaments. This includes Mosaic PEEK, Mosaic PEKK, Mosaic TPU, and even Mosaic Matrix, the company’s own carbon fiber-reinforced Nylon material.

For users looking for something a little less potent, the company has also developed a lower temperature configuration of the system called Element. Both Element and Element HT feature the Palette X material handling system, enabling them to print with eight different filaments simultaneously, much like the Array 3D printing system.

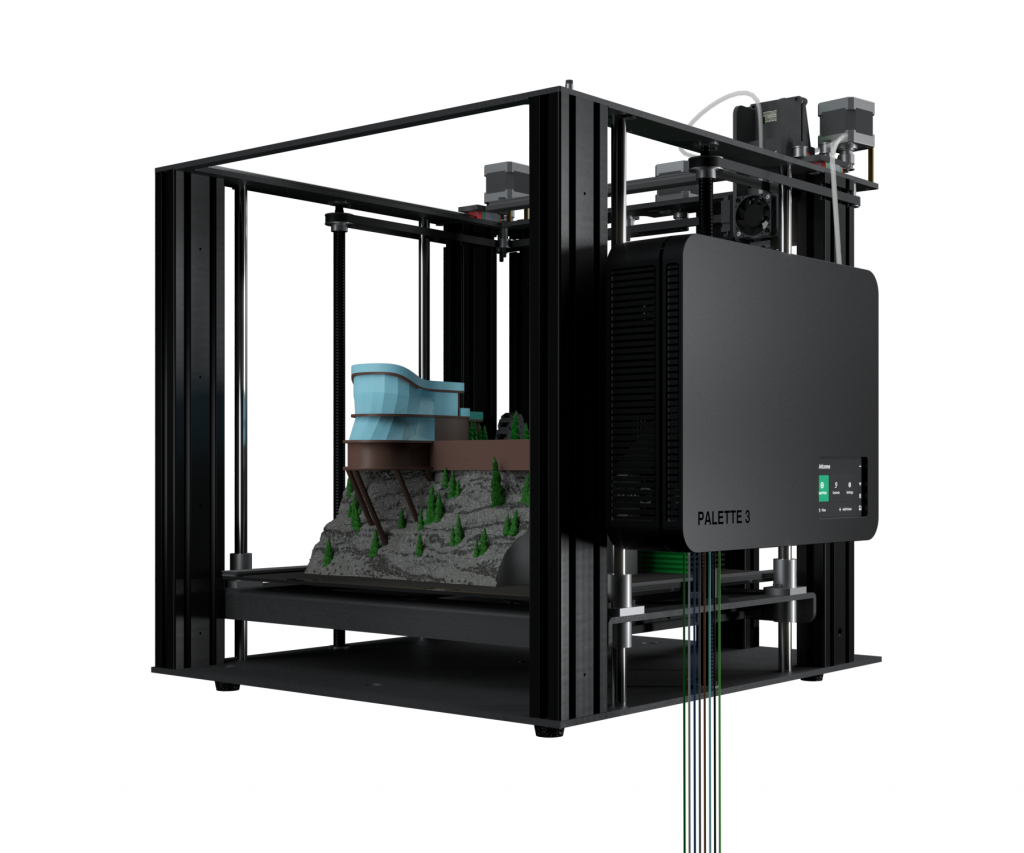

The Palette 3 and Palette 3 Pro

But what if you don’t need an Element 3D printer either, and just need the multi-material printing capabilities for an existing third-party system?

The Palette 3 and Palette 3 Pro are the latest versions of the company’s multi-material filament switching technology. Based on the embedded Palette X system, the Palette 3 and Palette 3 Pro allow for real-time switching between four and eight filaments respectively, and are offered as standalone devices for integration into existing FFF 3D printers.

Technical specifications and pricing

Below are the technical specifications for one individual Element HT 3D printer.

Array and its high-performance variant, Array Production, will be available from December 2021. The systems start at $59,999. Element and Element HT will begin shipping in November of 2021, starting at $5,999 and $9,999 respectively. The Palette 3 is priced at $599 while the Palette 3 Pro is priced at $799. The devices will begin shipping to customers as early as June 2021.

| Build volume | 355 x 355 x 355mm |

| Bed temperature | 120°C |

| Chamber temperature | 80°C |

| Nozzle temperature | 500°C |

| Materials | 8 (with Palette X) |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Array multi-material 3D printing system. Photo via Mosaic Manufacturing.