Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

North America-based metal AM company Integrated 3D (i3D MFG) has signed a letter of intent with EOS at RAPID + TCT 2024.

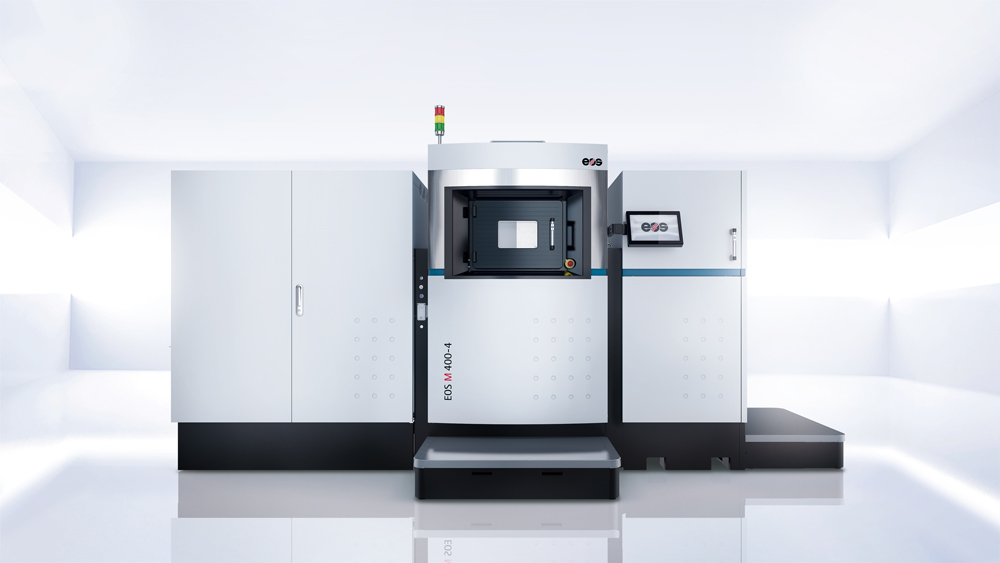

As a part of this agreement, i3D MFG will acquire twelve EOS M 400-4 metal 3D printers, each equipped with four lasers. This purchase will raise i3D MFG’s total EOS capacity to 36 systems at its production facility in Redmond, Oregon. Delivery for most systems is scheduled for 2024, with the remainder expected to arrive by 2025 and 2026.

“i3D’s strong partnership with EOS has had a demonstrable impact on our ability to serve broad customer-based needs for complex metal additive components. The combination of forward-thinking, resiliency, reliability and best-in-class technology is at the forefront of why i3D continues to expand our relationship with EOS,” said, Erin Mastroni, CEO of i3D MFG.

i3D MFG’s continued industry growth

According to the company, the EOS M 400-4 addresses the need for manufacturing large parts and complex components through metal additive manufacturing. Equipped with four 400-watt lasers and boasting a build volume of 400 x 400 x 400 mm, it facilitates serial production. Capable of handling diverse materials such as aluminum, copper, stainless steel, titanium, and tool steels, this system supports versatile applications across various industrial sectors.

Since 2013, i3D MFG has utilized EOS technology starting with the acquisition of an EOS M 280, employing EOS’ Direct Metal Laser Solidification (DMLS) laser powder bed fusion technology. Over time, i3D has broadened its customer base to include various industries such as space exploration, medical devices, clean energy, and automotive manufacturing.

Focusing particularly on aerospace and semiconductor sectors, i3D MFG’s expansion supports its efforts to bolster capabilities within the BTX Precision umbrella. Growth in rockets, satellites, and defense applications is contributing to both parties’ expansion in the high-precision manufacturing sector, says the company.

Recently, i3D MFG partnered with Authentise and United Performance Metals (UPM) to adopt the new Vendor Managed Inventory (VMI) platform. This collaboration aims to enhance material traceability, automate inventory management, and enable efficient scaling of production.

Stephanie Bonfiglio, Director of Integration at i3D MFG, emphasized the platform’s potential to improve material management and streamline additive manufacturing processes, underscoring its importance for agile operational growth in the industry.

Previously, i3D MFG partnered with Authentise in the AM-Verify project funded by the U.S. Department of Energy (DoE) via the Cybersecurity Manufacturing Innovation Institute (CyManII). The company aimed to focus on developing and demonstrating verification data streams to enhance cybersecurity in 3D printing, aiming to detect unauthorized access and ensure process integrity for improved reliability and quality assurance.

Benefitting from metal AM systems

Investing in metal AM systems enables companies to achieve complex designs, rapid prototyping, and customized solutions, enhancing efficiency, reducing costs, and gaining a competitive edge through innovative, sustainable manufacturing practices.

As a result, Incodema3D expanded its fleet with four additional EOS M 300-4 systems, bringing its total EOS metal AM systems to 28. With this step, Incodema3D continued its investment in the Direct Metal Laser Solidification (DMLS) technology.

Ideal for speed, efficiency, and versatile material capabilities, this acquisition of EOS M 300-4 systems, the company will be able to boost production capacity and ensure consistent part quality to meet increasing customer requirements effectively.

Industrial machining and metal AM services provider Wilting expanded its manufacturing capabilities by acquiring two single laser DMP Flex 350 and one DMP Flex 350 Dual metal 3D printers from 3D Systems. By doing so, the company aims to meet increased production demands and broaden material options, particularly for titanium and stainless steel.

These novel printers enable round-the-clock production of precise end-use parts, utilizing advanced features like quick-swap build modules and efficient powder recycling for cost-effective manufacturing solutions.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows from left to right: Jamie Goettler, Chief Revenue Officer, BTX, Marie Langer, CEO, EOS, Erin Mastroni, CEO, i3D, and Glynn Fletcher, President, EOS North America. Photo via EOS.