The UK’s Manufacturing Technology Centre (MTC) is where 3D printing and traditional manufacturing converge. Established as an independent Research & Technology Organisation (RTO) in 2010, the centre is the product of a collaboration between Loughborough University, the University of Birmingham, the University of Nottingham and TWI.

The centre’s privileged position in the market and well-cultivated contact list of over 100 industry members, places it in an ideal position for providing well-trained and talented individuals to the industry – a gap that the MTC struck upon in 2016 with the launch of the Lloyds Bank Advanced Manufacturing Training Centre (AMTC).

Now, the AMTC is looking for contributions to the development of its 3D printing and additive manufacturing skills competencies framework, due to launch later this year.

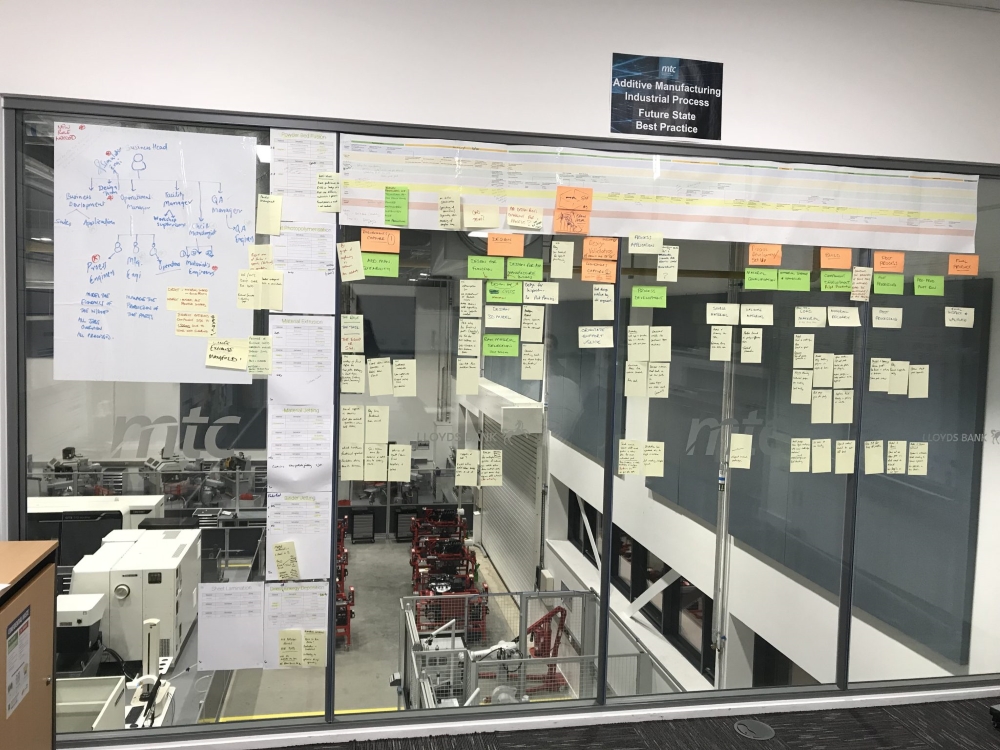

In a recent tour of the facility, I spoke to Martin Dury, Learning Design Manager, to learn more about the new, specialist additive, training to be offered at the AMTC.

Filling the additive manufacturing skills gap

The aim of the the MTC “is to create end-to-end vocational and apprenticeship programmes to enable a stronger AM industry for the UK.” The programmes will be offered to school-leavers aged 16 – 19, and engineers already in the industry looking to boost their skills.

Doctors and engineers of the MTC, working for members like Rolls-Royce, Airbus, GOM and Renishaw, lead all courses offered by the centre, giving a unique, industry-integrated perspective.

Apprenticeships can also be followed all the way through to degree level, gradually specializing when a candidate exhibits a flair for a particular skill, e.g. design for additive manufacturing, non-destructive testing and material development.

Taking the bull by the horns

Before additive manufacturing, the MTC has had success developing training programmes for advanced metrology, intelligent automation and advanced machining – once key skills gaps in industry-wide manufacturing.

“What we did,” explains Dury, “rather than wait for the national standards to catch up, we took the bull by the horns,”

“we got all of our experts over at the MTC to define the knowledge, skills and behaviours that they’d expect of an automation technician.”

From this, Dury and his team develop a framework describing the role and responsibilities of a person for a specified occupation, matching the national standards for engineering, but with overtraining in a specified area of interest. An early specialism makes candidates an asset to any company looking to take on new roles.

How to get involved

To develop 3D printing frameworks, and upskill/train more additive manufacturing engineers, the AMTC is looking for contributions from professionals throughout the industry. Dury comments,

“Right here right now, we’re probably the UK’s best-kept secret with regards to additive training.”

“The last thing I want is a real pertinent company saying ‘I wish I’d have know about that, I could’ve really helped steer that or given some rich content’ and I want to avoid that as much as possible.”

Contributions for the MTC’s additive manufacturing skills competencies framework close 31 March 2018. If you have an valuable insights in your industry and the skills desperately needed in additive, contact the MTC here.

For more on the latest opportunities in additive manufacturing and upcoming news from the MTC subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Adjudicate the most valuable 3D printing research institutes of the year. Make your nominations for the 3D Printing Industry Awards 2018 now.

Featured image shows metal 3D printed spheres from the MTC’s National Centre for Additive Manufacturing. Photo via The MTC