A group of Italian researchers has developed a 3D printed artificial skin that could be used to improve the tactile sensing capabilities of robots.

Researchers from Scuola Superiore Sant’Anna, Ca’ Foscari University of Venice, and the Sapienza University of Rome created the 3D printed skin which successfully mimicked the function of Ruffini receptors, a type of cell located on subcutaneous human skin tissue that detect stretching, vibrations, warmth, and pressure.

Once attached to a robot and combined with a deep learning algorithm based on a multi-layered convolutional neural network (CNN), the skin can estimate the force and point at which the robot comes into contact with an object, potentially enabling safer human-robot cooperation in the future.

3D printing artificial skin

3D bioprinted skin models and grafts have received increasing interest and development in recent years due to their potential uses for disease modeling, testing the efficacy of new treatments, and providing an alternative to animal testing.

Bioprinted skin has also gained attention for its potential for more effective wound healing treatments, such as the NOVOPLASM consortium’s cold plasma technology for treating infected burns and skin grafts, and the University of Birmingham and University of Huddersfield’s SLAM 3D bioprinting technique to treat chronic skin wounds.

3D printed skin is even being tested as far away as space, with astronauts on the International Space Station (ISS) developing bioprinted bandages made of their own cells that could be used to better heal flesh wounds in space.

Improving robotic tactile sensing

The Italian research group, however, is investigating bioprinted artificial skin for another purpose; improving the tactile sensing capabilities of robots. In particular, the findings of the study could potentially improve the performance of mobile robots that interact with humans in a range of real-world settings, such as public spaces, home environments, health care facilities, and offices.

By replicating the biological sensory processes of humans on existing and future robots, the researchers hope to improve the performance of mobile robots for a range of interactive and manual tasks, and reduce safety risks during operation alongside human workers in industrial environments.

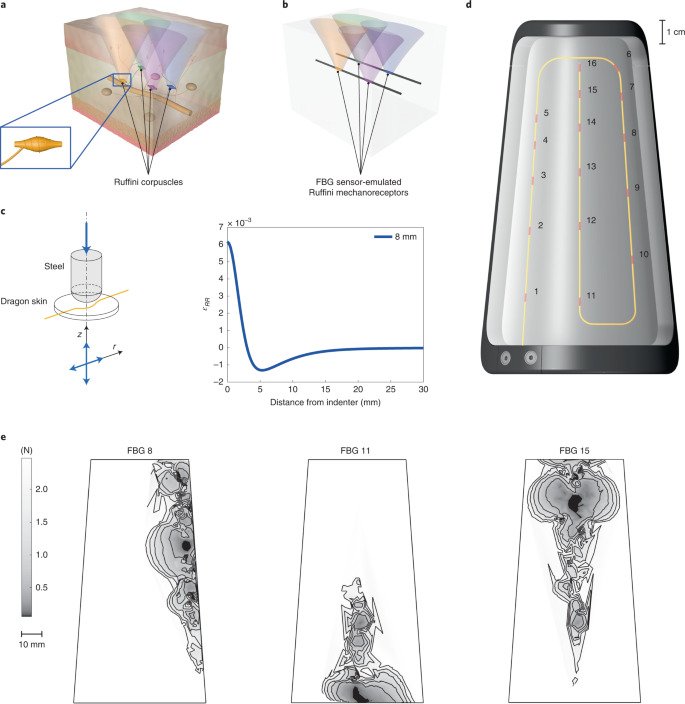

To achieve this, the team focused on replicating the function of Ruffini receptors, small and slowly adapting cells that detect interactions between the skin and external objects and stimuli, like heat, pressure, and contact.

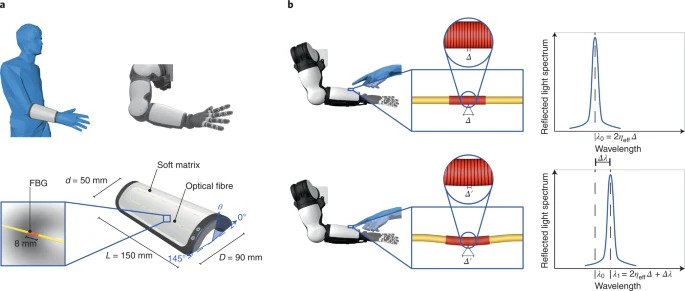

The researchers 3D bioprinted an 8mm-thick soft, curved and stretchable polymeric layer integrated with a 430mm-long optical fiber. The biomimetic ‘skin’ resembled a patch of human forearm, while the optical fiber contained photonic fiber Bragg grating (FBG) transducers capable of mimicking the functionality of Ruffini receptors.

The skin was then fitted to the robot to provide it with the capability of detecting stimuli in its surrounding environment.

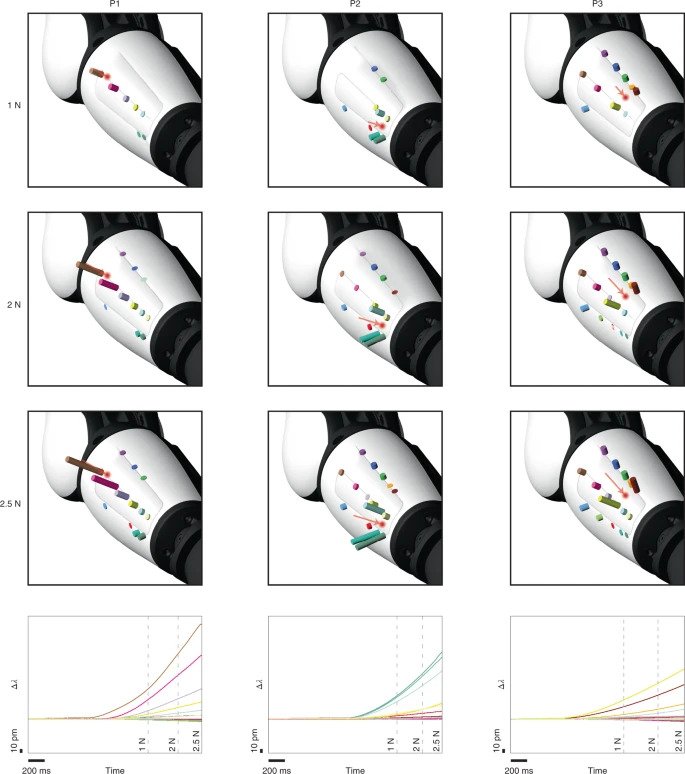

To decode the FBG sensor outputs, the team developed a CNN-based deep learning algorithm and multi-grid neuron integration process that informed robot of the force and point of contact of an external stimuli. The researchers then put their bioprinted skin and algorithm to the test through a series of simulations, within which it reportedly achieved “very promising results” in predicting the force applied to the robot and where it was applied.

Within the paper, the researchers state their findings could pave the way towards AI-integrated artificial skins enabling safer human-robot cooperation in the future. Going forwards, the team says their bioprinted skin could be implemented on a variety of humanoid robots, as the modular skin patches can be pieced together to fit different robot architectures and shapes.

As such, the next step in the researchers’ study is to investigate the extent to which their bioprinted skin can be applied to other robotic systems.

Further information on the study can be found in the paper titled: “Functional mimicry of Ruffini receptors with fiber Bragg gratings and deep neural networks enables a bio-inspired large-area tactile-sensitive skin,” published in the Nature Machine Intelligence journal. The study is co-authored by L. Massari, G. Fransvea, J. D’Abbraccio, M. Filosa, G. Terruso, A. Aliperta, G. D’Alesio, M. Zaltieri, E. Schena, E. Palermo, E. Sinibaldi, and C. Oddo.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the 3D printed artificial skin. Image via Nature Machine Intelligence.