The Wolfson Centre for Bulk Solids Handling Technology, part of the University of Greenwich at the Medway campus in Kent, will be hosting a week-long online short course on AM powder handling set to take place from 13 – 17 July.

Aimed at professionals working in powder processing, the comprehensive course will deliver the skills and knowledge necessary to understand the critical aspects of powder handling and management. No prior training or industrial experience is required to take part, as newcomers and veterans alike are encouraged to sign up.

What will the course cover?

‘Powder Handling and Flow for Additive Manufacturing’ will focus on both metal and polymer powders. The first few sessions, which will provide a basic overview and introduction to the subject, are intended to get everyone up to speed while the later stages of the course will delve deeper into the intricacies and quality considerations. Presentations, demonstrations, and discussions will be used to cover all of the key points with (essential) informal coffee break sessions peppered throughout. Each day will begin at 9:30 UK time and all five sessions must be attended for course completion.

Monday will kick off with a general introduction from the presenters followed by the basics of powder behaviour. As the week progresses, topics such as recycling issues, powder moisture, powder evolution, and powder characterization will be covered. The week will culminate with Friday’s 90-minute session on flow property control and a final review of the course contents.

Knowledge from industry leaders

The program itself will be presented by a trio of industry experts with a mountain of powder processing experience between them. Richard Farnish, a Senior Consultant Engineer at the Wolfson Centre, has been consulting and researching in the field for over twenty years. He’s worked on the design and troubleshooting of bulk solids handling systems both domestically and internationally.

Dr. Neil Harrison, a Materials Development Manager at Carpenter Additive, has over five years of academic and industrial experience in alloy design, powder behaviour, and powder evolution.

Finally, Claus Aumund-Kopp, a Group Leader for AM at the prestigious Fraunhofer IFAM Institute in Bremen, has been working closely with metal powders for powder bed fusion and binder jetting systems for over a decade and a half.

Pricing and further details

The course fee is £675 per delegate and you can book your place here. It will take place over MS Teams and a link will be sent to every delegate taking part prior to the start date.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

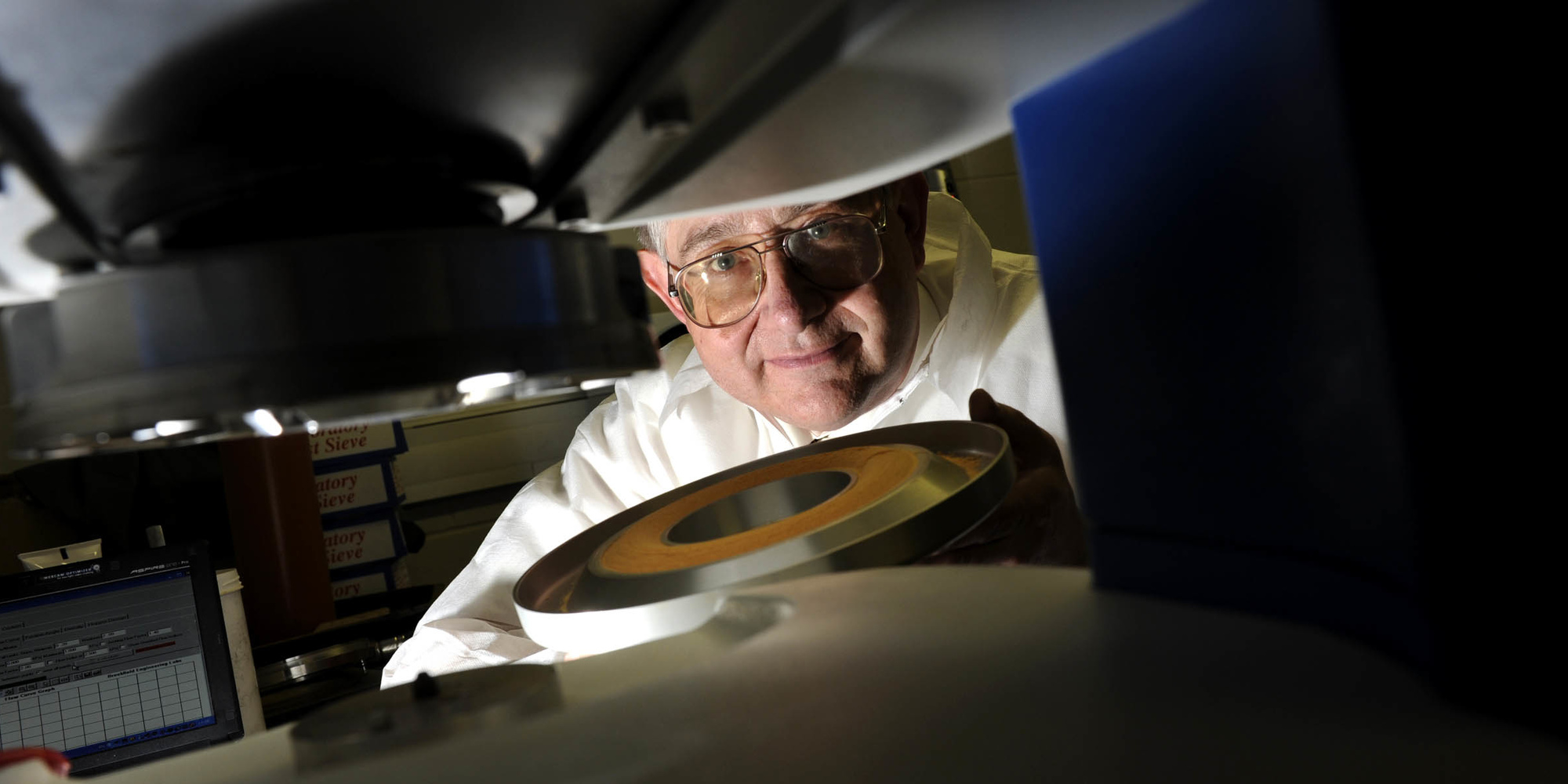

Featured image shows Prof Michael Bradley, Director of The Wolfson Centre for Bulk Solids Handling Technology. Photo via the Wolfson Centre, University of Greenwich.