German developer and provider of 3DMP metal 3D printers and technology GEFERTEC has introduced its novel arc80X series, aiming to meet the growing demand for larger-scale 3D metal printing using Wire Arc Additive Manufacturing (WAAM).

Built upon the WAAM process, GEFERTEC’s arc80X series combines metal inert gas welding with specialized CAM software and Sinumerik control architecture. The process offers high build rates and cost-effective material handling, making it suitable for industrial applications such as turbine component production in the energy sector.

arc80X series delivers cost-effective metal AM for mass production

GEFERTEC employs a CNC-controlled linear axis system for the machine’s kinematics, ensuring precise operation for consistent process stability and repeatability. In its 3-axis configuration, the system offers an assembly space measuring 2 x 2 x 2 meters and accommodates parts weighing up to eight tons.

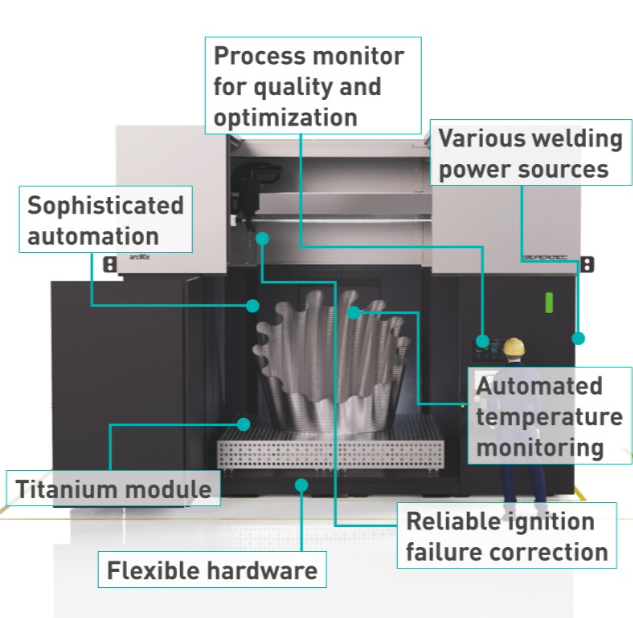

The 5-axis version is capable of printing parts with a maximum diameter of 0.9 meters and a height of 1.4 meters. This latest generation of machines introduces advanced automation features, such as integrated tool measurement, gas nozzle cleaning, wire cutting, and automatic replacement of wear parts, contributing to improved production efficiency and decreased personnel requirements.

Throughout the printing process, the process monitor meticulously records and stores all pertinent data, facilitating comprehensive documentation for quality assurance and process optimization. Moreover, the inclusion of an integrated pyrometer for measuring part temperature, coupled with active component cooling, significantly contributes to achieving optimal part quality. Additionally, the optional inert gas box feature enables printing in a closed inert gas atmosphere, allowing for the processing of delicate materials like titanium.

Previously, many prospective users of the innovative 3D printing process hesitated to invest in their machines, often due to a lack of expertise within their organizations. GEFERTEC will now provide an extensive service package to address this challenge. Leveraging its expertise, GEFERTEC process technicians and CAM engineers will assist customers in seamlessly transitioning their parts manufacturing processes to arc machines.

Services offered include technical feasibility assessments and identification of potential efficiency improvements through parts screening. Additionally, GEFERTEC experts can aid in qualification processes, enabling customers to fully capitalize on the capabilities of arc machines and commence 3D printing with WAAM even in the absence of in-house experts, says the company.

A closer look at WAAM applications

WAAM, also known as Directed Energy Deposition-Arc (DED-Arc), is an additive manufacturing technique for creating metal structures. Applications of WAAM can be found in various industries like aerospace, automotive, and shipbuilding, among others. For instance, Australian 3D printer manufacturer AML3D sold its large-scale ARCEMY ‘X-Edition 6700’ WAAM metal 3D printing system as part of the US market entry strategy, aiding the U.S. Navy’s adoption of WAAM technology.

Facilitated by BlueForge Alliance, a U.S. Department of Defense (DoD) intermediary, this will help supply components to its U.S. Navy’s submarine industrial base. AML3D’s CEO, Ryan Millar, explained the long-term strategic partnership with the U.S. Navy, focusing on scaling up submarine production through advanced additive manufacturing. This initiative aligns with AML3D’s strategy to prioritize ARCEMY product sales, particularly in the U.S. maritime and defense sectors.

In an interview, Filomeno Martina, CEO of WAAM specialists WAAM3D, discussed the company’s position and long-term vision during Formnext 2023. Founded in 2018, WAAM3D aims to industrialize the WAAM process and offers machinery, software, and materials for large-scale wire-based direct energy deposition.

Complementarity to metal AM, Martina highlighted WAAM technology’s suitability for large-format industrial parts. WAAM3D targets sectors like aviation, showcasing cost savings and environmental benefits, while also addressing supply chain challenges. Its software packages, including WAAMCost and WAAMCtrl, optimize production costs and enable process monitoring, enhancing confidence in part quality and reducing failed builds.

What are the 3D printing trends the industry leaders expect to see this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows GEFERTEC arc80X. Image via GEFERTEC.