AIM3D, a Germany-based developer of multi-material 3D printing technology, has announced the launch of its latest 3D printer at Formnext 2021.

Operating on the firm’s proprietary composite extrusion modeling (CEM) process, the new ExAM 510 can print with up to three different materials at the same time, including polymers, ceramics, fiber-filled composites, and even metals. The technology is known for its compatibility with readily-available injection molding pellets, which makes it significantly faster than conventional FFF processes.

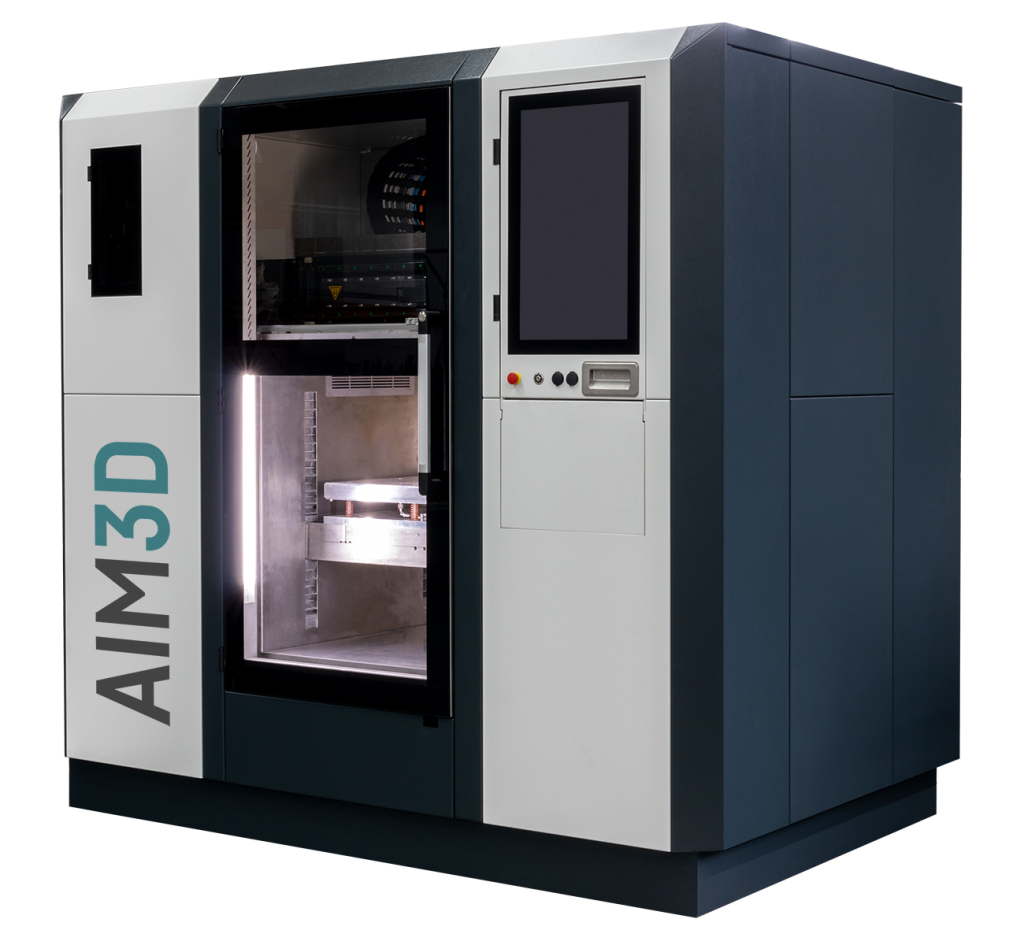

Intended as a successor to the previously launched ExAM 255, AIM3D’s new ExAM 510 printer sports a larger-format build volume, improved print precision, and faster print speeds. The printer’s applications stretch far and wide, covering use cases in aerospace, automotive, and healthcare.

CEM 3D printing with AIM3D

Founded in 2017 in the city of Rostock, AIM3D set out with the goal of developing a multi-material 3D printing technology that combines performance and affordability. The backbone of CEM 3D printing is the company’s patent-pending AIM3D CEM E-1 extruder, a device capable of processing several types of granular materials up to 3mm in diameter. As it stands, AIM3D currently offers one commercially available 3D printer – the ExAM 255.

The novelty of the technology is that it’s designed to work with the pellets used in injection molding, including metals like stainless steel and high-performance polymers like PEEK.

In the case of metal builds, only the polymer component of the pellets is melted. This initially leaves a fragile green part made of metal powder bound by the surrounding polymer. The next step of the workflow involves debinding the plastic and, finally, sintering the printed part to increase its density and form a stable metal component.

The ExAM 510 3D printer

AIM3D’s latest 3D printer features a hearty build volume measuring 510 x 510 x 400mm, and can process up to two build materials and a support material simultaneously. One of the major advantages of pellet-based 3D printing is also the excellent print speed potential. The CEM E-1 extruder, specifically, delivers material flow rates up to ten times faster than run-of-the-mill filament extruders, enabling the ExAM 510 to achieve build rates of up to 250 cm³/h.

One noteworthy feature of the ExAM 510 is its extensive material capabilities. To enable printing with higher temperature materials, the system’s build chamber can be heated to 200ºC, allowing for the processing of engineering-grade polymers such as PEEK, PEI, PSU, and PPS. As far as metals and ceramics go, users will be able to work with 316L stainless steel, titanium, copper, aluminum oxide, zirconia, silicon carbide, and more.

According to AIM3D, a material can be tested in around two working days and validated for production in 5 – 10 working days on the ExAM 510. Injection molding pellets are also significantly cheaper than equivalent 3D printing filaments. For example, PEEK filament is priced at around €700/kg, whereas PEEK pellets can be purchased for €50/kg, leading to significant material cost savings on the ExAM 510.

Clemens Lieberwirth, CTO of AIM3D, said, “The further development of our patented ExAM 255 machine into the ExAM 510 is a technological leap for us. So you could say we are now offering a faster, bigger, hotter and more precise CEM process technology for Additive Manufacturing.”

Technical specifications and pricing

Below are the technical specifications for the AIM3D ExAM 510 3D printer. The system is expected to be ready for series production by Formnext 2022. Readers can contact AIM3D for a quote.

| Build volume | 510 x 510 x 400mm |

| Materials | 3 (2 build + 1 support) |

| Build rate | Up to 250 cm³/h |

| Chamber temperature | Up to 200°C |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ExAM 510 3D printer. Photo via AIM3D.