Engineers at Northwestern University have created a novel soft, flexible device that allows robots to move by mimicking human muscles through expansion and contraction.

For this research, the actuator (device) was used to create a cylindrical worm-like soft robot and an artificial bicep. The robot navigated tight spaces, and the bicep lifted a 500-gram weight 5,000 times without issue. Made from standard rubber, each robot costs about $3, excluding the small motor that helps the actuator change shape. This approach is much cheaper than traditional rigid actuators, which can cost hundreds or thousands of dollars, says the team.

Led by Professor Samuel Truby, the June and Donald Brewer Junior Professor of Materials Science and Engineering and Mechanical Engineering at Northwestern’s McCormick School of Engineering, along with Taekyoung Kim, a postdoctoral scholar and first author of the paper, the research also included contributions from Pranav Kaarthik, a Ph.D. candidate in mechanical engineering. Titled “A flexible, architected soft robotic actuator for linear, servo-driven motion,” the study, was published in Advanced Intelligent Systems journal.

“Roboticists have been motivated by a long-standing goal to make robots safer,” said Northwestern’s Ryan Truby, who led the study. “If a soft robot hit a person, it would not hurt nearly as much as getting hit with a rigid, hard robot. Our actuator could be used in robots that are more practical for human-centric environments. And, because they are inexpensive, we potentially could use more of them in ways that, historically, have been too cost prohibitive.”

Bioinspired soft actuators: enhancing robot mobility and flexibility

Rigid actuators have traditionally dominated robot design, but their rigidity and safety issues have led researchers to explore soft actuators. Inspired by human muscles that contract and stiffen simultaneously, Truby and his team developed a new type of actuator.

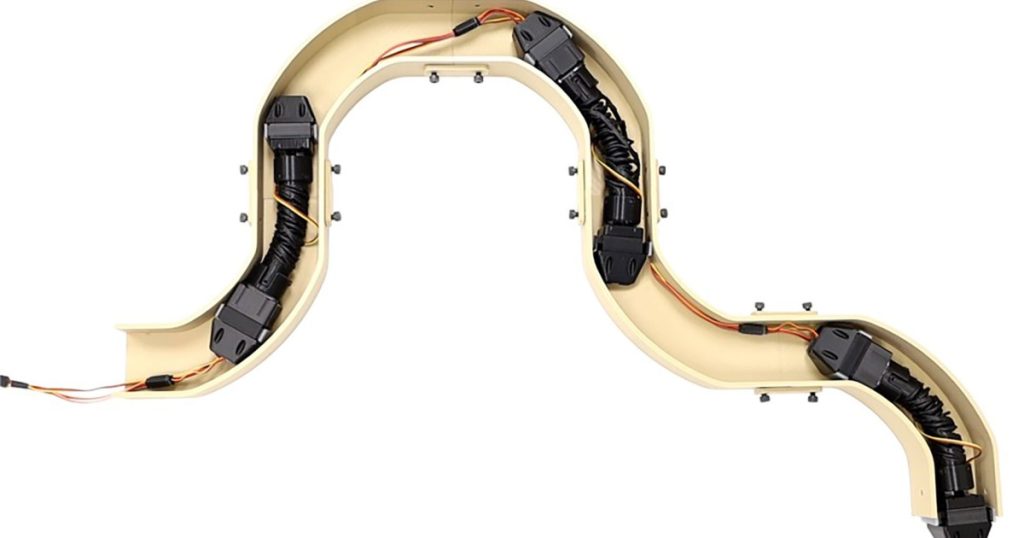

The team 3D printed cylindrical “handed shearing auxetics” (HSAs) from rubber, which allows for unique movements like extending and expanding when twisted. Previous HSA versions made from rigid plastic resins with expensive printers lacked flexibility and deformability, according to the researchers.

Kim addressed these limitations by using thermoplastic polyurethane, a material found in cellphone cases, and a cost-effective desktop 3D printer. This made the HSAs softer and more flexible, though twisting them for extension and expansion remained a challenge.

Earlier soft actuators needed multiple servo motors for twisting, which complicated fabrication and reduced softness. Kim resolved this by adding soft, extendable rubber bellows to act as a deformable rotating shaft, enabling a single servo motor to extend or contract the actuator in either direction.

Adding the bellows allowed Kim to create a crawling soft robot using a single actuator. This 26-centimeter-long robot, moving at over 32 centimeters per minute, can navigate confined spaces and stiffens when the actuator extends, unlike earlier soft robots.

As per the team, the ability of soft actuators to stiffen while operating, similar to human muscles, is a significant advancement. This bioinspired feature enhances movement capability and expands the range of tasks soft robots can perform compared to traditional robots.

3D printed muscles on the move

3D printed muscles represent a promising area of research with the potential to significantly impact muscle repair and regeneration methods. An example includes the Italian Institute of Technology (IIT) researchers developing a robotic hand equipped with SLA 3D printed artificial muscles, called GRACE actuators, which replicated human-like grip efficiency.

Weighing just 8 grams, these actuators could lift objects up to 1,000 times their own weight and allowed the robotic hand to perform complex movements such as bending fingers and twisting the wrist. The GRACE actuators, printed from a resin membrane, demonstrated the potential of 3D printed muscles to mimic biological functions with increased versatility and strength.

Back in 2017, scientists at Columbia University developed a 3D printed synthetic muscle capable of lifting up to 1,000 times its own weight. The team described an actuator that mimicked human muscle expansion and contraction using a PMSD-based silicone elastomer mixed with ethanol.

When an electric voltage was applied, the ethanol’s phase change caused the material to expand and contract significantly. This muscle combined high strain and stress with low density, showing promise for creating lifelike bionic body parts for simple manual tasks.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows a new crawling robot designed by Northwestern researchers navigates a tight, pipe-like environment. Image via Northwestern University.