Nominate now for the 3D Printing Industry Awards 2023.

Imperial College London 3D printing topology optimization software spinout TOffeeAM has been awarded an Innovate UK grant to undertake a new project which seeks to revolutionize the design of cold plate heat exchangers.

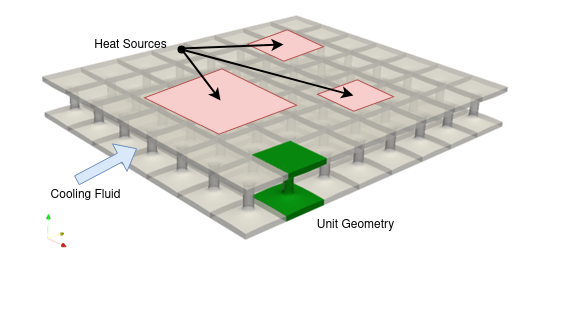

The project is titled “Multiscale Optimization Framework for the Next Generation of Heat Exchangers.” The team hopes that its novel cold plate designs will unlock superior thermal efficiency and reduce CO2 emissions, “contributing to a greener future.”

TOffeeAM has partnered with Imperial College London and the National Aerospace Technology Exploitation Programme (NATEP) to undertake this project, which will begin this month. The 14-month project will leverage the potential of multi-scale methods which promise unprecedented performance improvements with a simplified design approach for engineers, TOffeeAM claims.

A new design for cold plates

According to TOffeeAM, the market size for heat exchangers is set to reach $26.26 billion by 2030. Looking to tap into this growing market, the project aims to develop an alternative design framework for cold plates, which they claim will unlock a “new era of thermal efficiency.”

To achieve this, the project will leverage novel multiscale methods developed by researchers in Imperial College London’s Department of Aeronautics. Ultimately, the team hopes to produce designs that offer superior heat transfer capabilities and require less pumping energy to operate than conventional cold plate systems.

What’s more, the team claims that the project will result in heat exchangers that not only offer high performance but also help to reduce CO2 emissions. Moreover, the team claims that the project will minimize computational and experimental waste.

TOffeeAM’s additive manufacturing journey

Founded back in 2019 by Francesco Montomoli, Marco Pietropaoli and Audrey Gaymann, TOffeeAM was born out of a four-year research project at Imperial College London. The start-up develops generative design software for engineering applications, with the company’s goal being to “make engineers go further and faster.”

It didn’t take long for the UK-based company to gain recognition, with TOffeeAM being selected as one of the 2020 formnext start-up challenge winners. This award followed a $1 million seed funding round earlier in 2020. The funding round was led by venture capitalist firm IQ Capital, and supported by the Royal Academy of Engineering and Imperial College London’s Techcelerate program. TOffeeAM used this funding to hire engineers and additional staff, expand upon its existing engineering capabilities and further develop its customer base.

TOffeeAM’s software offering is designed to optimize the topology of 3D printed components to better suit their target applications. The company’s software can also optimize entire systems, reducing the overall number of parts, and increasing the resilience of systems as a whole.

Additionally, the company’s multi-physics, simulation-driven software employs advanced algorithms and optimization techniques to automate the entire design process. This allows users to generate optimal designs in minutes and hours, as opposed to weeks and months.

TOffeeAM claims that its software can create robust parts 20 times faster and 40 percent more efficiently than with conventional 3D printing methods. The software has already been utilized within industrial production, creating coolant systems for gas turbines that exceed the performance of current heat exchangers.

3D printed heat exchangers

The production of heat exchangers is nothing new within additive manufacturing. In early 2022, UK-based alloy design firm Alloyed showcased a highly-optimized 3D printed copper cooling plate for use in high-temperature computing systems such as data centers, as well as general liquid cooling systems.

The system featured a 3D printed lattice geometry that combined functionality and performance, while also minimizing material usage. Additionally, thanks to its monolithic structure, Alloyed’s cooling plate is both simpler and more efficient than traditionally assembled cold plates. The company partnered with copper powder specialists JX Nippon Mining & Metals to produce the cooling system.

Elsewhere, earlier this year Australian heat transfer specialist Conflux Technology partnered with German-based space rocket manufacturer Rocket Factory Augsburg to embed 3D printed heat exchangers into an orbital rocket.

The heat exchanger parts are 3D printed using Conflux’s Monel K 500 metal alloy material in conjunction with EOS M300-4 Direct Metal Laser Sintering (DMLS) technology. Part of the Australian Space Agency’s Moon to Mars Initiative, the project is being funded by the Supply Chain Capability Improvement Grant Program which awarded Conflux $1 million AUD last year.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a group of researchers using TOffeeAM’s optimization software. Image via ToffeeAM.