UAE-based 3D printing bureau Immensa and assurance and risk management specialist Det Norske Veritas (DNV) have released what they are calling the “world’s first” global guideline on digitizing spare parts.

Global manufacturing supply chains are becoming increasingly fraught. Conflict in Ukraine, attacks on shipping in the Red Sea and Gulf of Aden, and increased tension in the Taiwan Strait and South China Sea have emerged as prominent threats to imports. Disruptions associated with climate change, trade protectionism, and other unforeseen circumstances also threaten supply chain security.

This has led organizations to adopt digital inventories of spare parts which can be 3D printed on-demand and at the point of need.

Immensa is the largest digital manufacturing firm in the Middle East and North Africa (MENA) region. Its new global guideline primarily targets the energy and power sectors, which reportedly spend over $90 billion on spare parts annually.

The companies claim the guideline complements national industrial initiatives in the Gulf region. They believe the new offering will stimulate sustainable economic growth and enhance the global competitiveness of industrial bases worldwide.

Immensa’s CEO, Fahmi Al Shawwa, called the development a “game changer” for supply chains and asset security.

“Energy companies are demanding the very latest cutting-edge innovation to produce parts locally, and national industrial strategies are focused on the same goal for their wider manufacturing sectors,” he added. “We are delighted to support the Middle East’s rapid growth, and to be a pivotal player in the $91 billion global energy spare parts market.”

A new guideline for spare part digitization

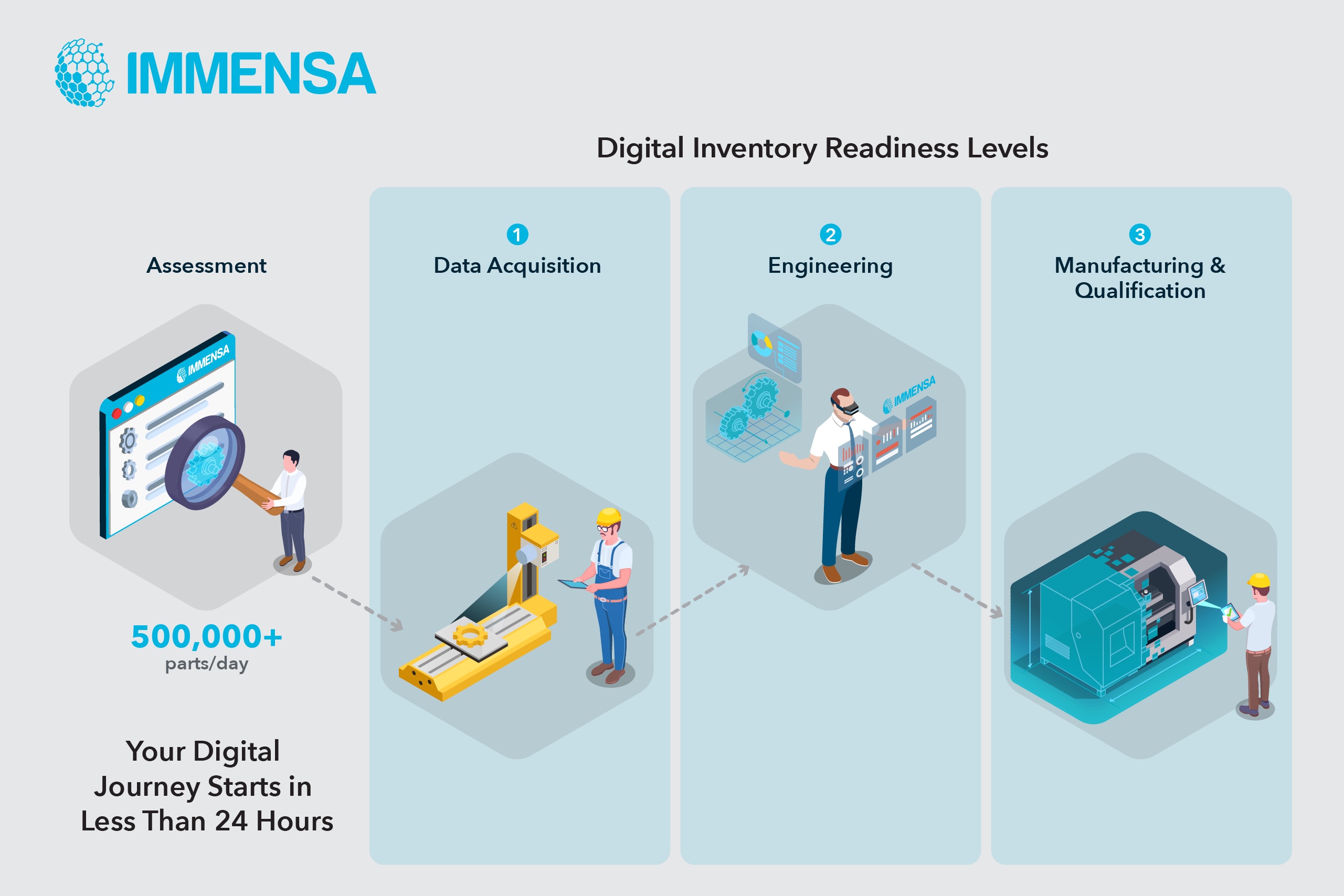

The new guideline reportedly offers a streamlined step-by-step process for solving supply chain and inventory management challenges.

It includes guidance on assessing physical parts for digitizing potential; converting selected physical parts into digital twins for inclusion in a Digital Inventory system; and On-demand Manufacturing. The latter includes recommendations for those using 3D printing as a “variable spare parts strategy,” enabling the timely delivery of high-quality parts.

A team of 10 experts from Immensa and DNV established the guideline over five months, combining their knowledge of additive manufacturing, digital warehousing and quality assurance. The team also leveraged customer insights in the development process to ensure the criteria are accessible to purchasers and manufacturers.

Notably, the new offering will address $30 billion of annual losses faced by energy companies around the world. According to Fahmi, Immensa is already leveraging the procedures with global customers. Its artificial intelligence (AI) process can assess 500,000 parts in 24 hours.

Established in 1864, DNV is a big name in the technical standards space. 65% of the world’s offshore pipelines are designed and installed according to the company’s specifications. The firm’s Global AM Practice Lead, Dr Sastry Kandukuri, believes its new framework “marks a significant milestone in additive manufacturing.”

The guideline launch follows Immensa’s recent efforts to grow its global footprint through strategic partnerships. Earlier this year, the company announced a collaboration with Pelagus 3D to improve 3D printing supply chains, expand OEM networks, and enhance service offerings for maritime and offshore customers. The company claims this will capture a new $2 billion market opportunity in the maritime vertical.

3D printing-enabled digital inventories

The 3D printing industry is witnessing increasing adoption and development of digital inventories and online inventory management systems to digitize access to spare parts.

The 2024 Additive Manufacturer User Group (AMUG) Conference saw Würth Group’s subsidiary Würth Additive Group introduce its Digital Inventory Services (DIS) platform. The new offering is designed to securely transmit intellectual property globally. This reportedly improves quality assurance processes and facilitates the prompt distribution of OEM parts.

Similarly, German 3D printing software developer 3YOURMIND offers its Digital AM Inventory module which centralizes access to 3D files and production data. Part of 3YOURMIND’s 3D printing workflow software, the platform offers a cost-effective alternative to storing spare parts in physical warehouses. Through the digital inventory, users can store part specifications and production requirements, visualize 3D models, and conduct material and parts orders.

Elsewhere, Wibu-Systems offers OMNIPlus. This online 3D printable spare part inventory was developed in collaboration with German bus manufacturer Daimler Buses and metal 3D printer manufacturer Farsoon Technologies. It allows Daimler and Setra Bus operators to access 3D printed spare parts as needed.

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows Immensa’s 3D printing Digital Inventory offering. Image via Immensa.