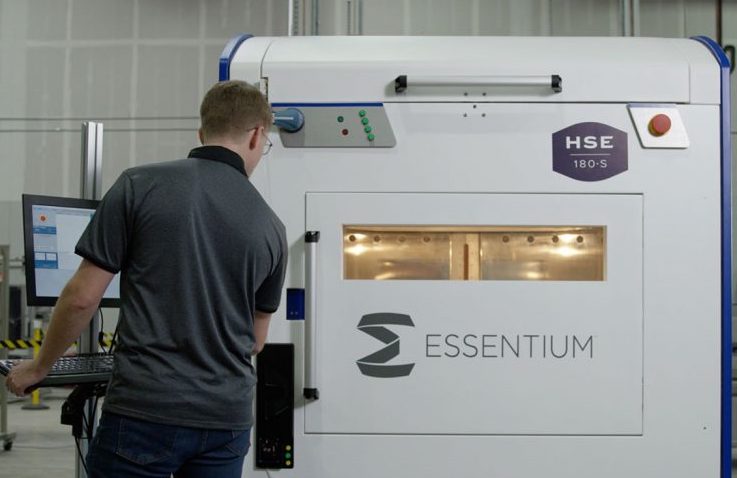

Essentium, Inc., a Texas-based company that makes industrial 3D printers, has started Essentium Parts On-Demand (EPOD), an in-house production service based on its High Speed Extrusion (HSETM) 3D printing technology. The service gives manufacturers access to Essentium’s engineering know-how and an open AM ecosystem of solutions for making a lot of parts quickly and cheaply.

Essentium says companies are currently more careful not to overextend themselves when the economy is bad because they don’t want to lose money. But, while CFOs are reconsidering capital spending, demand for parts remains high. Customers can use Essentium’s engineering-grade filaments with EPOD’s “polymer-to-part” services to create components using unique filaments developed and manufactured in-house. The EPOD service gives customers the advantages of HSE printing and access to the complete Essentium ecosystem without raising capital expenses.

The company says early adopters of EPOD services are already reaping the rewards. One customer in the oil and gas business employed HSE’s printing capability and capacity to print PEEK parts, while another in the Aviation Technical Operations industry used the polymer-to-part solution to make 100+ housings built of a bespoke material with flame-resistant qualities.

The EPOD service now operates nine HSE 3D printers, with plans to increase to 15+ by the end of 2024. Customers benefit significantly from the faster printing speeds of HSE printers when compared to other machines. According to a market survey of 40+ part manufacturing shops worldwide, EPOD provides cost savings for 100% of the geometries and materials studied, distinguishing it from 13 other industrial extrusion-based service providers.

EPOD’s sales director, Joe Anguiano, has been appointed to drive growth and client satisfaction. Joe held senior sales positions in the AM business prior to his current employment.

Ongoing economic and geopolitical upheaval is taking its toll on manufacturers, who have been compelled to defer capital spending and seek other means of procuring parts explained Anguiano. The sales director of EPOD added the service will let businesses use the HSE platform, including high-performance materials, to make components at the proper economics without incurring capital costs. Training new users on additive manufacturing will also be crucial in assisting them in making the transition from prototyping to industrial-scale production. “It’s a win-win for manufacturers and the AM industry,” said Anguiano.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Essentium HSE 180 ST 3D printer. Image via Essentium.