Speaking with Juan Mario Gomez, the CEO of Xact Metal, gave me insights into his journey of transitioning from a thriving career in the aviation sector to steering a startup in the 3D printing industry. With a background in engineering, Gomez’s voyage commenced in designing jet engines, which gradually fostered an entrepreneurial spirit within him. His tenure at General Electric (GE) was marked by remarkable achievements, including spearheading the growth of a venture from inception to a quarter-billion-dollar sales figure. However, the allure of the entrepreneurial world led him to delve into the realms of 3D printing, a decision well-timed with the market’s demand for cost-effective printing solutions.

Xact Metal’s inception was a meeting of Gomez’s business acumen and two young engineers’ innovative spirits from Penn State University. Despite starting with a modest budget, their ingenuity yielded a functional metal 3D printer, marking the commencement of Xact Metal. Their journey, however, was full of challenges, as the pandemic induced a severe drought in orders, plummeting to a meager $10,000 in a quarter. Gomez recalls, “It was brutal.”

However, the tribulations galvanized their resolve. Leveraging his past experiences, Gomez navigated through the crisis by focusing on cash viability rather than downsizing, a strategy that emanated from his seasoned stint at GE—the subsequent quarter witnessed a resurgence in orders, hinting at a promising trajectory ahead.

Gomez cherishes the agility and customer-centric approach inherent in a startup culture, contrasting it with the cumbersome administrative layers often found in colossal corporations. He remarks, “I love that it’s a young company that’s entrepreneurial, that’s moving very quickly, that’s focused on the customer.”

Read more in the 3D Printing Industry Executive Interview series.

Xact Metal Aims to Democratize 3D Printing with Affordable Quality

Xact Metal has embarked on a mission to make high-quality metal 3D printing accessible to manufacturers at affordable prices. This mission stems from an observation that while larger, costlier machines cater to affluent customers, there’s a significant market segment desiring to tap into the value of 3D printing but deterred by the high initial investment.

Gomez illustrated the company’s hypothesis: “We’re going to focus on the customers that want to access the value of AM, but they can’t start the business case. These are businesses that need a lower price machine.” The aim is to provide a 3D printer that maintains a high-quality output while significantly cutting costs, potentially priced at a third or half compared to high-end counterparts.

Xact Metal’s approach is rooted in lean operations and cost-effectiveness, aimed at lowering entry barriers to 3D printing technology. This strategy, according to Gomez, has not only been validated by the robust demand observed during trade shows but also the continued interest even amidst budget constraints caused by the pandemic. He reminisced, “When the budgets got released, the orders started coming in pretty quickly.”

By introducing smaller, cost-effective machines and now expanding to mid-sized machines, Xact Metal is progressively working towards filling a market gap. Gomez mentioned the palpable interest at trade events, where potential customers, previously priced out, are now engaging in conversations, a testament to the traction Xact Metal’s approach is gaining. This endeavor, as Gomez puts it, continues to be about increasing the market’s accessibility to 3D printing technology, a venture that is already seeing validation in the market dynamics observed.

Xact Metal’s Evolution: Marking Milestones Amid a Pandemic

Xact Metal has marked significant milestones since its inception in 2017, navigating through the pandemic and adjusting strategies to continue its growth trajectory toward making 3D printing technology accessible and affordable. Reflecting on the journey, Gomez shared the firm’s key turning points and the strategies that bolstered their growth despite COVID-19 setbacks.

Launching initially with a small machine, the company took its first steps into the market and began shipping products by December 2018. They faced a challenge with their initial XY scanning system, which, while producing quality parts, fell short on speed, especially for thin parts like heat exchangers. Gomez noted, “We just couldn’t move quickly enough, so we ended up having to pivot the company to a galvo-based architecture.”

This pivot wasn’t just a reaction to a technical hiccup, but a strategic move to enhance the product range by introducing higher power systems and multi-laser systems focusing on speed and productivity. “The name of the game is about speed. Productivity kicks in pretty quickly,” remarked Gomez, emphasizing the importance of adapting to market needs.

Amid the pandemic, the company harnessed the pivot to lay the foundation for larger machines, aligning with its vision of catering to a broader market segment. They also expanded their reseller network to over 26, chiefly in North America and Europe, focusing on local expertise for sales and service. Gomez highlighted the importance of local support, stating, “Local expert resellers who also install and support locally within a four-hour drive.”

Gomez shared his perspective on the necessity of connecting with customers locally, explaining, “If we cannot answer the customers’ questions we are slowing everything down. We need to support the customer locally. That allows scalability as well.”

Reflecting on the success of their strategy, Gomez noted a gratifying trend where existing customers refer new ones, validating not just the product quality but the overall customer experience they have cultivated.

On the product front, Xact Metal has developed a line that caters to varying customer needs. The discussion delved into the specifics of their product range, such as the XM200C, representing their initial XY gantry system, and the newer XM300G and XM200G, where ‘G’ stands for galvo, showcasing the shift to a galvo-based architecture aimed at enhancing speed and productivity.

The XM300G, boasting a larger build volume and enhanced power through more lasers at 400 or 700 Watts, Xact Metal aims to address production demands. This strategic product line evolution underpins Xact Metal’s objective to not only cater to the existing market but to expand it by making 3D printing technology more accessible and affordable.

Take 15 seconds let us know the impact of this article below:

Xact Metal Targets Untapped Market Segments through Affordable, High-quality 3D Printing Solutions

While the current market size hovers between $1 and $2 billion, Gomez envisions a broader spectrum awaiting penetration. “Metal is an area growing and driving itself heavily into production environments,” he notes.

The conversation pivots to emerging technologies like wire and powder-based systems and binder systems, accentuating the trade-off between speed and part quality. Gomez appreciates the strides made by companies like Desktop Metal and HP but maintains that the real market readiness lies in powder bed fusion (PBF), the technology Xact Metal is vested in.

With a price point of around $100,000 to $150,000, Xact Metal’s offerings aim to cater to machine shops and injection molding companies that find the conventional price tag for metal 3D printers prohibitive. “Injection molding applications sound appealing, but if the machine costs $3 million, they can’t afford it,” Gomez remarks.

However, market development and education are pivotal to unlocking this latent demand. Gomez acknowledges the time and effort required to not only present a cost-effective solution but also ensure that quality is not compromised, which could deter potential adopters.

On the pricing aspect, Gomez pointed out the importance of lowering the costs of both machines and materials like powder, which currently constitute a significant portion of part prices. “The machine depreciation schedule dictates 70% of the price of a part,” he notes, signaling the critical role of pricing in industry acceptance. Discussing the depreciation period for 3D printing machines, an aspect influencing the price point and, consequently, market acceptance. Gomez advocated for a ten-year depreciation timeframe, aligning with the pace of technological evolution.

Gomez highlights the substantial role of standardization in propelling the industry forward, mentioning how adhering to OEM-specified ISO standards has eased the process of selling their machines. “Standards play a big role. Companies like to be able to say, we’re adhering to the ISO standard,” he states.

The Competitive Landscape in the 3D Printing Industry

The CEO of Xact Metal delved into the competitive landscape confronting his firm, a player in the burgeoning 3D metal printing sector. Gomez highlighted the competition, underlining different phases of application evaluation where Xact Metal battles against giants like EOS, SLM, and Concept Laser, implying a level of technical scrutiny in customers’ evaluation phase.

Discussing regional competition, Gomez observed numerous small, regional competitors but noted their struggles in broadening their market reach beyond local or national boundaries. The crux, according to him, lies in commercializing the technology, a hurdle that many stumble upon.

Shifting focus globally, the discussion spotlighted the market dynamics in Germany, the US, and China. Gomez acknowledged Germany’s lead in additive technology acceptance but underscored the surging interest in the US, driven partly by efforts to bolster its manufacturing competitiveness. The Chinese market presents a complex scenario with its “in China for China initiative” and the existing geopolitical tensions, which, as per Gomez, compound the challenges of market entry and competition.

Reflecting on the Chinese competition, Gomez conceded to China’s growing stature in metal 3D printing but expressed confidence in competing on price and quality, given that labor cost isn’t the overriding factor in machine assembly.

Gomez’s detailed insights underscore a nuanced global competition landscape, emphasizing the necessity for strategic navigation amid shifting market dynamics and geopolitical undercurrents to foster growth and market penetration in the 3D metal printing domain.

The firm’s forward strategy also encompasses the commercialization of the XM300D machine, hinting at a focus on moderately-sized systems as opposed to venturing into significantly larger machines.

Additionally, partnerships form a crucial part of Xact Metal’s game plan. The firm allied with Oqton and Addiguru to integrate artificial intelligence in enhancing machine productivity, a move aligned with the industry’s broader trajectory towards smart, AI-driven solutions. Gomez acknowledged the necessity of such technological alignments, emphasizing the overarching goal to make machines “more productive” and “smarter.”

The dialogue also touched upon the complementary nature of additive manufacturing with other technologies in the manufacturing sector. Gomez elucidated that despite advancements, additive manufacturing wouldn’t replace other technologies but would rather work in tandem, underscoring a symbiotic growth trajectory.

Reflecting on the firm’s ethos, Gomez stressed a customer-centric approach, which he believes is pivotal for sustainable growth in the competitive 3D metal printing arena. The CEO envisions a foundational strength built on quality, speed, and impeccable customer service as the linchpin for success, a traditional yet robust model in the rapidly evolving metal 3D printing space.

Nominations are now open for the 2024 3D Printing Industry Awards.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

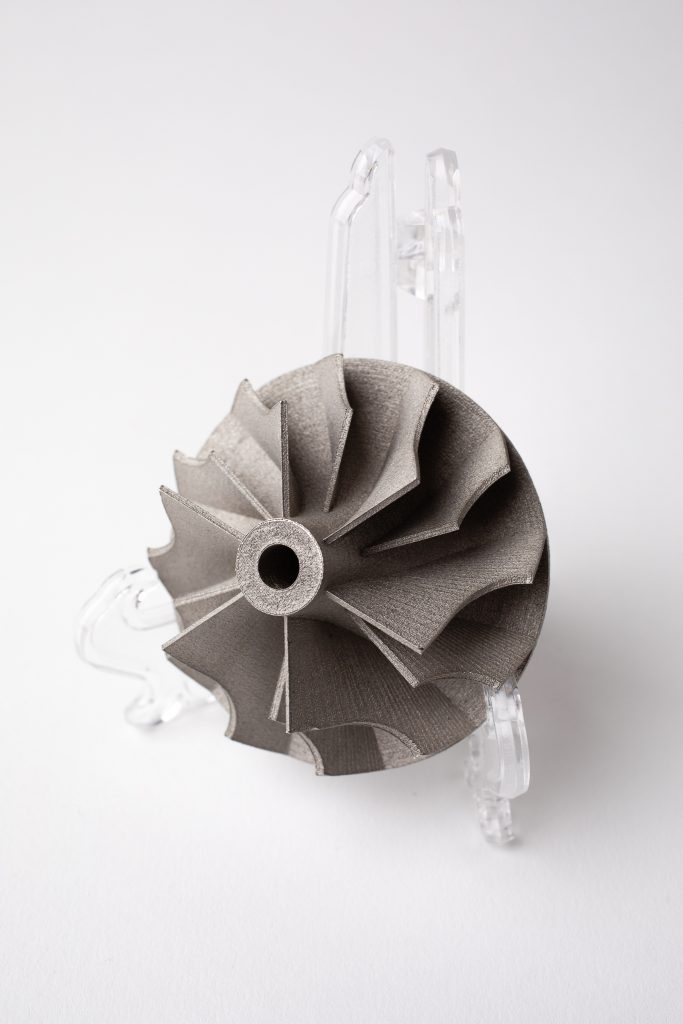

Featured image shows 3D printed bronze feature test in focus with three various stainless steel feature tests behind 316L, 15-5, 420. Photo via Xact Metal.